Astro Pi: 3D-Print Your Own Flight Case

Background

Back in December, British ESA astronaut Tim Peake took two specially augmented Raspberry Pis, called Astro Pis, to the International Space Station (ISS) as part of his six-month mission. These Astro Pis are running experimental Python programs written by school-age students; the results will be downloaded back to Earth and made available online for all to see.

To satisfy the safety requirements that ESA and NASA have for small payloads aboard the ISS, we had to build the Astro Pi flight unit and put it through a rigorous qualification process.

At £3000 each, you can see why we only ever made eight of them. Why do they cost so much? Each half of the case is milled out of a solid block of aerospace-grade aluminium using a five-axis CNC mill. The two halves are then bead-blasted to give them a matt surface, then they’re anodised with a special coating to aid thermal radiation. After that, there’s some manual touch-up work, followed by installing the Raspberry Pi hardware and, finally, laser-etching the markings and logos.

That all adds up!

However, to quote from the original blog post where we announced it:

This will not be available to the public to buy because we’re only making a small number of them. We may however, in due course, release an object file so schools with a 3D printer can print one themselves.

With today’s blog post we’re making good on this promise!

The first attempt

Initially we just tried to 3D-print the original CAD files to see how hard it would be. The trouble with 3D printers is that they use hot thermoplastics, which can bend and sag under their own weight.

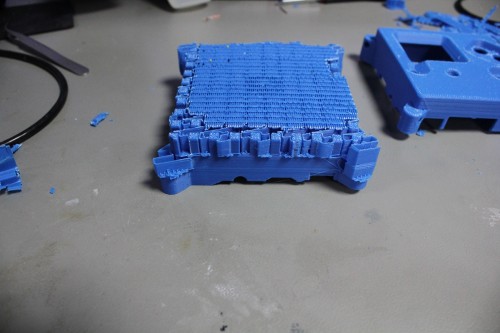

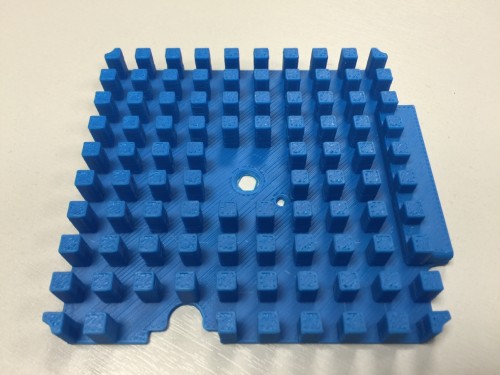

To avoid this, the printer creates what’s known as scaffolding and rafting to ensure the structural integrity of the object during the printing process. The user has to peel off this support material to get the original object they were trying to print. Any part of the object that overhangs will cause support structure to be built below it to prevent sagging. So the lower part of the flight case, with the grid of pins, came out chock full of the stuff:

Scaffolding and rafting that must be manually removed

After about 20 minutes with a pair of pliers, and accidentally snapping one of the corner pins, we decided this would be too frustrating for most users.

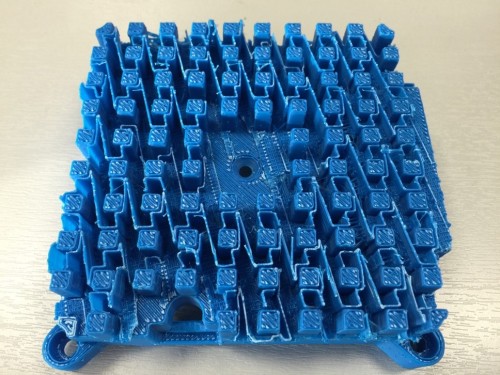

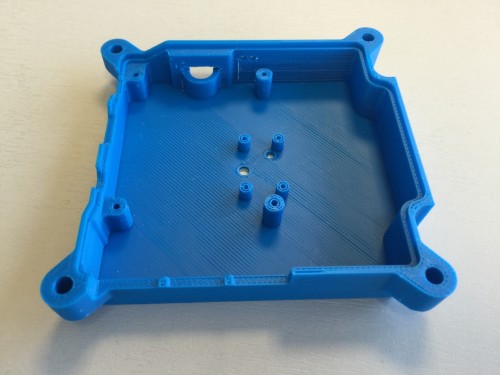

The base with scaffolding and rafting still remaining

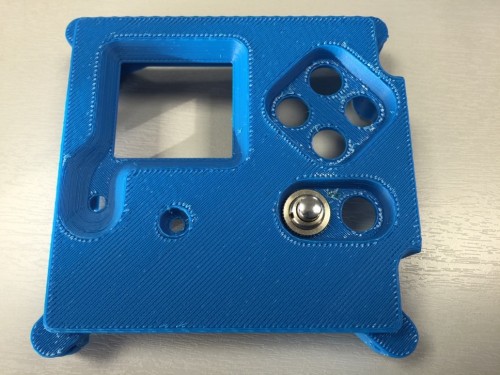

The lid was slightly better. It was printed with the outer surface of the case facing downwards, to avoid support structure filling the internal cavity. But this meant that the outer surface came out with rafting all over it, and removing this resulted in a characteristic stringy finish that doesn’t look great.

The lid, printed with outer surface facing down

So we set about modifying the design so that even users with low-end 3D printers would be able to successfully print it, with minimal scaffolding and rafting.

Several attempts later

Many thanks to Ben Martin from Solid Models in Cambridge for running off so many test prints for us, and to Jonathan Wells (who did the original CAD work) for the many tweaks and changes. Our own Creative Producer, Rachel Rayns, contributed lots of 3D printing experience which led to these decisions. It was most definitely an iterative process!

The first change we agreed on was to slice off the heat sink on the base, so that it could be printed in the opposite orientation. That way it would have nothing overhanging to cause support structure to be built between the pins.

We then sliced off the top of the lid so that it could be printed with the clean side facing upwards, meaning the stringy side would face down.

That was a lot nicer looking. So with the lid and heat sink sliced off, it meant the two original middle bits were left as discrete parts.

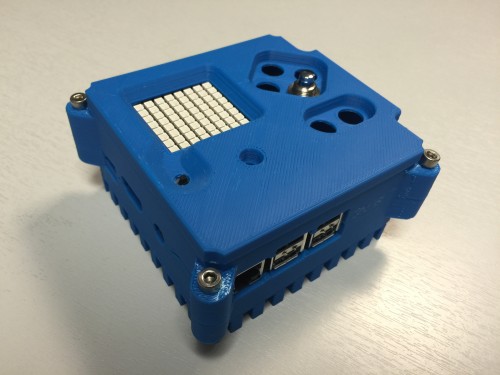

We also removed the pillars between the USB and Ethernet ports because these snapped off easily. Finally, for convenience, we changed the corner bolt enclosures from a sunken captive screw to a straight-through M4 nut-and-bolt design.

You can use epoxy adhesive (or similar) to join the heat sink to the base and the lid to the middle. When the Raspberry Pi and Sense HAT are installed it’ll end up looking something like this:

The assembled flight unit, still missing a few buttons

New resource

To guide you through the assembly process we’ve created a brand new educational resource that covers everything from downloading the STL files and getting the fixtures and fittings you need right through to testing that you’ve wired up the push buttons correctly. Click through and take a look:

https://www.raspberrypi.org/learning/3d-printed-astro-pi-flight-case/

We’re really looking forward to seeing the cases you make – please show us by tweeting pictures to @Astro_Pi and @Raspberry_Pi.

By far the most exciting benefit of owning an Astro Pi flight unit is the ability to prototype and test code that could be run on the International Space Station. Head over to the Astro Pi website now to get involved in the new coding challenges!

FAQ

Where are the STL files?

On GitHub.

Why are there four files, not two?

We sliced the case into four layers to minimise the amount of scaffolding and rafting that needs to be printed; it also keeps printing time down. The text of the blog post above explains this in more detail.

Can we modify the STL files?

Yes. They are released under the Creative Commons attribution license so you are welcome to modify them. Please note that GitHub has a great STL viewer and also has a 3D file diff, which could be useful for tracking changes.

Can we have the original CAD?

Currently, no. Raspberry Pi needs to retain the ability to be the sole manufacturer of the space-qualified Astro Pi flight unit. You are welcome to reverse-engineer the STL files we’ve released today, though.

How do you fit the hardware inside it?

The educational resource we’ve written covers this in great detail: check it out here.

I don’t have access to a 3D printer, but I really want this case. What can I do?

You may be able to find one at your local hackspace. You can also find local 3D-printing services through the website Hubs.

28 comments

Alan Mc

*Runs to makerlab to get to the 3D printer first.*

Bravo and thanks Dave and all the other contributers.

Gordon

Well done in getting this completed. Look forward to seeing people’s creations.

Where can we get the buttons from?

David Honess — post author

It’s in the resource linked above:

Manufacturer: APEM

Manufacturer Part No: 104350003

Phil Atkin

I’d love to see somebody with a few thousand quid to spare running these up on Shapeway’s new sintered aluminium process …

Andy

Try http://i.materialise.com . They’ll 3D print your uploaded models in quite a few materials – incl. metals. I have bought several camping stove caps in sintered steel from them.

Phil Atkin

Didn’t know they did sintered steel – their standard ‘steel’ looks the same process as Shapeways, an inket print of glue onto a bed of powder, then a bath in liquid bronze to replace the glue with bronze. Will dig deeper looking for sintering …

pithagoros

So what materials are people going for? GP Plastic or high detail resin?

Graham

Brilliant, I didn’t notice you had said you might make the 3D printer files available but great that you did

Patrick Wiatt

I can’t wait to get a demo one set up on my desk for the students to see!

Ian Steiger

Me too!

Andrew

Is this being made available to 3rd party manufacturers to freely copy and produce for sale or licensed to manufacturers, or is there a condition that prevents that?

I’m not a manufacturer wanting to make them myself, but I don’t have access to 3D Print and I was wondering if they are likely to be on sale as a finished product.

David Honess — post author

See the FAQ above; specifically

Can we modify the STL files? and

I don’t have access to a 3D printer

Hope this helps :)

Andrew

Hi thanks for the reply David, I did read the FAQ. Asking a 3DHub member to do a one off is going to be frighteningly expensive, hence my hope that a manufacturer will do volume production and reduce the cost.

Leo White

I’ve just ordered some more filament, so hopefully I can have a go at printing this over the weekend. In fact my wife is positively encouraging me to do so, despite not normally getting involved in my Pi related shenanigans..

Rich

Well I know what I’ll be printing tonight. :)

KG2V

Darn it, came to ask for the original files, as I have access to a mill. Sigh. Right there in the FAQ – a no go. A nice, really solid, low RFI RPi case would be very nice

aremvee

Meh – I usually prefer to print money (oops)

Brandon Fesser

Great work! Would it be possible to get copies of the STLs with fewer modifications and slicing for those of us who are more skilled at 3D printing? Particularly without the captive nut and screw hole modifications. Pretty please?

(Yes, I read the “Can we have the original CAD?” I’m not asking for the originals, just something closer to them.)

Jim Manley

OUTSTANDING!!! We received a very nice, low-cost ($249 Black Friday on-line from http://www.bn.com, now $399) XYZprinting da Vinci Jr. 1.0 WiFi 3D Printer that has a 5.9 x 5.9 x 5.9 in. build volume. Based on the size of a Pi and SenseHAT, this appears to be within that limit. Can anyone confirm what the outermost dimensions of this print are? Thanks!

Will the AstroPii remain on the ISS after Tim Peake leaves? If so, will other astronauts take over the educational mission? If that’s the case (pun fully intended :) ), will there be more experiment/code competitions for students located outside the UK to be uploaded, as was indicated in earlier blogs/comments when the UK student competitions were ongoing?

David Honess — post author

The full width is 109 x 109 mm, so hopefully that will fit.

The software that comes with your printer should be able to tell you though.

To answer your second question yes, there is a new competition in progress right now where you can get your code uploaded to the ISS: https://astro-pi.org/coding-challenges/

We’re currently in talks with ESA about French ESA Astronaut Thomas Pesquet using the Astro Pis in future: http://www.esa.int/Our_Activities/Human_Spaceflight/Astronauts/Thomas_Pesquet

Jim Manley

Thanks very much Dave, for both the answer and your work to help pull this off. I see that, once again, the new challenge is only for students in the UK, and that’s very disappointing. Whatever happened to the “INTERNATIONAL” in the ISS? Yes, I understand that students outside the U.S. don’t seem to have as many opportunities to participate in STEM programs, let alone space programs, as students in the U.S. seem to, but there’s a bell curve here, too. Half of the population that rarely makes it onto TV or YouBoob lives in rural and agricultural areas, which are largely intellectual deserts. That’s why meth labs and heroine distribution are becoming industries in their own right – there is no hope of escaping such places without a strong educational foundation.

However, many U.S. schools in those regions have budding international programs that span the now-archaic boundaries drawn by incredibly-uninformed colonialists. The high school where I’m teaching has students from over 50 countries who speak over 62 languages, and that doesn’t even count the software development languages! :D Additionally, we offer the full spectrum of Cambridge International curriculum as honors courses, so if anywhere should be included in such competitions, schools like ours should be.

I’d like to encourage Clive, Carrie Anne, and the rest of the education team at the Foundation to help us get Picademy established in our tech-isolated location in the rural Southern Midwest and Upper South, as well as including schools with large international student bodies in the space fun. I know the U.S. astronauts are being sent Microsoft HoloLens units, but that’s more of a sad brand promotion publicity stunt of something that even developers won’t get until the Summer … for $3,000 a pop, and it isn’t even slated to become a product in the foreseeable future, so I don’t see how that connects to education at all. As one Bard might say if alive today, “The Pi’s the thing … ” ;)

Michael

Did anybody find some good replacements for the original pushbuttons? The “space” ones are way to expensive.

David Honess — post author

Have a look here: http://cpc.farnell.com/pro-power/ppw01067/switch-rnd-pb-red/dp/SW03225

Leo White

Those look similar to the ones I ordered (http://www.ebay.co.uk/itm/271464025582). They arrived today and fit nicely! Have yet to wire them up tho…

Nigel Savage

Hi Dave,

The http://cpc.farnell.com/pro-power/ppw01067/switch-rnd-pb-red/dp/SW03225 buttons (and associated colours) are too large for the case without modding it – I found out the hard way :(

Daniel

I have a problem to find the right 2×20 pin PCB header. Can some one say wich of these both are the right?

https://www.adafruit.com/products/2223

https://www.adafruit.com/products/1979

Thanks you!!!

David Honess — post author

Hi there, the pins need to be 15mm long. So the first one you linked has 10mm long pins, so that one is out. The second one has 10mm pins but stacked up, that’s the one I would go for.

You can also get the correct part from Toby Electronics;

http://www.toby.co.uk/content/catalogue/products.aspx?series=309AE-xx-xG-xx-1555

part 309AE-40-SG-1Z-1555

Also, in the future CPC may be selling a parts bundle for the flight case. Which will contain everything you need including the buttons.

There would be an economy (with cheap buttons) and premium version (with the APEM buttons used in the real flight units).

Daniel

Thank you.